|

|

|

|

|

1.

What are the differences with

regular chargers ?

|

|

The main cause of damage

done on battery is caused by

the sulfate which is attracted

to battery electrodes. Conventional

chargers simply charges voltage

of the battery, which does not

take account of battery type

and attributes. As a consequence,

it results in significantly

reduced charging efficiency

and stability of the battery

due to damages. Also, conventional

transformer type chargers are

much less energy efficient,

heavier and bigger.

|

|

|

Therefore, in comparison

with other regular chargers,

our products provide more suited

restoration processes through

optimized regeneration & charge algorithms.

This is the main difference

from regular chargers, which

only provides simple, fixed

voltage & current when charging.

Without considering the battery

condition or type, there is

high possibility to potentially

damage the battery from overcharging.

In order to resolve it,

there will be a staff required

to manually check for voltage

of the battery when charging,

which will lead to poor efficiency.

|

|

In case of OPTIMORE Regenerator,

we have reached the highest

regeneration efficiency by applying

Micom Smart Control System and

Optimal Pulse Regeneration Algorithm

Data that includes most of the

battery types used in the world.

As a result, OPTIMORE successfully

minimizes damages done on the

battery while restoration process

using High-frequency Pulse.

Batteries can be

restored back to original performance

level through charging and regenerating

with their useful life extended

by up to two or three times

as long.

|

|

With the world exclusive high-frequency pulse and restoration algorithm, it can restore inside cells by melting sulfate crystals on the plates and grids, and it can improve its capacity and life span as almost similar as new battery condition. OPTIMORE Battery regenerators were developed by the World Exclusive Technology, and these make the remarkable micro-bubble featured de-sulfation effects by the real high-frequency pulsations. And these can make the highest charging performance for used-batteries. OPTIMORE technology is the revolutionary invention for battery life extension and cost savings!

|

|

|

2.

Summary of Features

|

|

¡Ü Smart Control

System by MICOM

-

Control minute electric current

& voltage depending

on the

type of battery

-

Restoring and recharging for

large capacity batteries

-

Minimizes damage to electrodes

and restrain accumulation

of

sulfate on electrodes

-

Lowest power consumption

|

|

|

¡Ü Optimized HF

Pulse regeneration and charging

algorithm

-

Utilizes special pattern information

on various battery kinds and

characteristics with High-frequency

Pulse

-

Prevents electrical / physical

damage when restoring and

charging

batteries

-

Prolongs battery lifecycle

|

|

¡Ü Wide Application

Range

-

Can regenerate and charge medium-capacity

batteries

-

Can restore and charge GEL and

AGM VRLA type batteries

-

Can restore and charge up to

48V of multiple batteries simultaneously

|

|

¡Ü Safety

-

Maintains low battery temperature

during restoring

(Input over-voltage

protection)

-

Stable current / voltage supply

(Control input voltage variation

function)

-

Prevents potential hazard caused

by high battery temperature

|

|

|

|

|

3.

OPTIMORE Technology

|

|

OPTIMORE

Battery Regeneration Technology

is the world first invention for

removing sulfates by real High-Frequency

Pulse. Our High-Frequency Pulse

technology is the most advanced

method among all battery regeneration

methods for removing sulfates and rejuvenate its electromotive force.

|

|

Why

OPTIMORE¡¯s technology is very

different from the other company's

technology ?

|

|

SMPS makes desired voltages

by high-frequency switching

after changing Alternating Current

(AC) into Direct Current (DC).

In this, if generated electricity

was supplied to a battery, due

to resisting load in a battery

itself, it would have a high

possibility that a component

in SMPS (FET) would be

damaged. Thus, since output

shock from SMPS should be relieved,

by using a condenser and a choke

coil, resisting load inside

of a battery would be minimized.

Therefore, actually supplied

thing from SMPS to a battery

can be Direct Current (DC) rather

than High-Frequency Pulse. SMPS

can actually makes High-Frequency

Pulse, however ironically, SMPS

of other competitors prevent

to output High-Frequency Pulse

due to the damage of their regenerators.

|

|

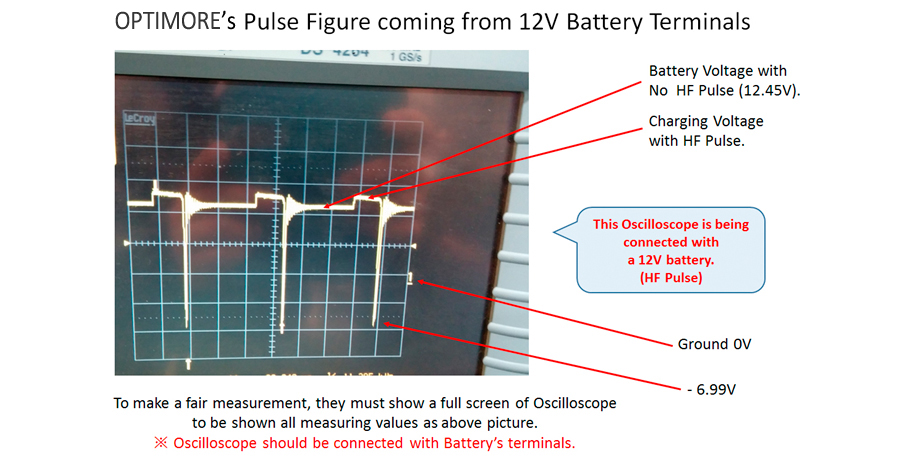

Because of this technical

limitation, there was no company

can solve the problem providing

real High-Frequency Pulse to

a battery from regenerator directly.

That is a reason that

regenerators using High-Frequency

Pulse could not be boosted and

commercialized so far. All

the other competitors insist

that their technology is based

on High-Frequency Pulse, but

they can show some signals through

screen of Oscilloscope by connecting

two Probes coming from the transformer

of SMPS. However, that can be

wrong measurement and pulse

which doesn't enter into a battery

gives any help to the regeneration.

Definitely, real High-Frequency

Pulse should be confirmed by

connecting probes to battery

terminals. Since High-Frequency

Pulse is too much weak, it can't

provide any help for regenerating.

Due to those limitations, since

direct connection to the battery

terminals with Oscilloscope

can be showing as direct current

(DC) only, so other companies

never show it to customers.

OPTIMORE regenerators are the only

regenerator which can make the

superior regeneration by supplying

real High-Frequency Pulse included

current at the same time.

|

| ¡ß

|

Adoption of MICOM

Smart Control System enables

OPTIMORE regenerator to provide

variable input / output voltage

and current for batteries. It

enables to control minute electric

current & voltage at optimal

high-frequency pulse ways when

restoring and charging batteries

of different kinds. This makes

it possible to restore and charge

large capacity batteries while

significantly reducing weight,

size and cost compared to the

conventional transformer types.

To cater for the different

voltage needs of different countries,

it covers variable input

voltage and power.

|

| ¡ß

|

With our proprietary

know-how and technology, we

achieved the highest charging

efficiency by integrating optimal

HF Pulse charging algorithm

classified by battery types

and attributes used worldwide.

It can restore batteries back

to its original performance

level through charging

and regenerating without any

electrical and physical damages

done to the battery.

It also

extends the functional life

of the battery by up to

two ~ three times as longer.

|

| ¡ß

|

Through the use

of Smart Control System and

Pulse Regeneration Charging

Algorithm, OPTIMORE Regenerator

minimizes damages done to battery

with its ability to automatically

control minute current and voltage

inputs / outputs to prevent

over-voltage. It is an innovative

pulse power technology for restoring

and charging at the same time,

which is what makes us more

competitive than anyone else

in the market.

|

| ¡ß

|

When charging or

restoring, if the battery temperature

is too high, it could lead to

damage and possible explosion.

This is a very serious matter

when restoring and charging

battery. With OPTIMORE Regenerator,

there is no risk of damage or

explosion as it maintains temperature

level within acceptable range

through various algorithm of

HF pulse regeneration.

|

| ¡ß

|

OPTIMORE Regenerator

prevents temperature rise, which

is caused by unnecessary conversion

of current to heat while charging.

The power consumption

of OPTIMORE will be 10~20% only

compared to other oversized

transformer type regenerators.

|

|

|

|

|

|

|

|

|

|

|

|

4.

Technology Differentiation from other products

|

|

1. Different from other products

that are designed to restore

by

hardware, the regenerator

is designed to restore via software

by micro-computer algorithm.

Thus, its circuit is

simple to reduce its failure

rate.

|

|

|

2. The software regeneration

enables it to restore any of

battery

including the new one

by modifying and complementing

the

method fast.

|

|

3. Using each push buttons of MD-200C/300T/400E and MD-700M

provide very

easy to use by user-friendly

design.

|

|

4. New technology pattern

by type / function of the battery

is

built in it to control

the method of Pulse by battery

type. (AUTO)

|

|

5. Its high frequency pulse

and high frequency current restores

up to 50% faster than existing

other regenerators.

|

|

6. Weight is much less than

SCR regenerators with low frequency.

Thus, all machines are portable.

|

|

7. The most effective in

minimizing damage to electrodes

and in restraining sulphation

electrodes by using high frequency

pulse.

|

|

8. Built-in software algorithm

that searches for optimum frequency

to fit the battery capacity

by using a microcomputer.

|

|

9. Output power supply that

uses Switching Mode Power Supply

(SMPS) enables it to consume

power very small compared to

low frequency method.

|

|

10. High frequency pulse

enables it to control electric

/ physical damage of the battery.

|

|

11. Able to use as a battery

regenerator and charger with

large capacity.

(Recommend to

restore up to 400 Ah, but able

to restore up to 1,000 Ah : MD-400E / MD-700M).

|

|

12. Able to restore and charge

all kinds of lead-acid batteries

including GEL and AGM type ones.

|

|

13. Able to restore and charge

all kinds of electric forklifts and golf

carts up to 24V ~ 48V at once

and

up to 12V batteries x

2 batteries and 4 batteries(with MD-400E / MD-700M) at the same time.

|

|

14. Safe supply of voltage/current

(able to control deviation of

input voltage 80V - 240V) when

equal to and below 300Ah only.

Over 300Ah = Alternative

110 / 220V.

|

|

15. Less battery heat release

by restoring via pulse compared

to other products.

|

|

16. No risk of explosion

because the pulse regeneration

with micro bubbles.

|

|

17. Chargers and other regenerators

make big bubbles (What we call

¡°battery solution boils¡±).

But OPTIMORE shows smaller

or

micro-bubble figures.

|

|

18. The regeneration principle

is to remove sulphation similar

to that of ultrasonic cleaner

that cleans pollutants of glasses.

|

|

19. Built-in system to prevent

lightning, counter voltage and

internal heating with over current

protection circuit.

|

|

20. Monitoring and remote

control via a computer.

|

|

|

|

|

5.

Features of OPTIMORE

Regenerator

|

|

|

1.

Designed to the pulse regeneration

algorithm in a MICOM,

and it

can be a smart control. Automatic

restoration &

charging patterns

according to battery types &

conditions.

|

|

- Optimized high-frequency

restoring and charging. Depending

on each

different type of battery,

it automatically controls voltage

and current.

(Can

be restored and charged for

various input voltage and current

types of batteries - Fine

tuning of voltage and current)

- OPTIMORE Regenerators are designed

by a Micro Computer with optimized

regeneration algorithm software,

therefore, the circuit systems

are

simple and failure rate

seldom occurs. On the

other hands,

most competitor¡¯s

products are designed by hardware

systems.

|

|

2.

Acceptable Battery Voltages

:

Each unit supports up to DC 6V ~ DC 48V (MD-400E /

MD-700M),

DC 6V ~ DC 12V

(MD-200C / MD-300T)

|

|

- i.e. Same conditioned

12V batteries, OPTIMORE can charge

and restore

batteries with serial

connections up to 8 batteries

(12V x 4 pcs. = 48V)

at the

same time.

- Forklift

/ Telecom Batteries 2V x 24

cells = 48V bank

at the same time.

|

|

3.

Supported medium capacity of

battery : Each unit restores

up to

400Ah battery.

|

| i.e. 2V battery with

a medium capacity, OPTIMORE

supports up to 400Ah capacity, it can restore larger volume

batteries such as Forklifts¡¯, Golf Carts¡¯ and UPS batteries.

|

| 4.

Compact Design & Performance

(MD-200C / 300T / 400E /

700M)

|

|

Despite compact size and

improved mobility, it handles

larger volume batteries with

much better restoring and charging

quality.

|

|

5.

Easy & Convenient User Interface

Screens

|

|

Programmed on optimized charging

algorithm classified by battery

kind and feature developed by

our proprietary

know-how and

technology.

|

|

6.

Monitoring in

All of OPTIMORE Regenerators

|

|

Monitoring print out by USB connection with PC (¡®USB AM-AM Cable with double-shielded¡¯ Optional).

|

|

7.

Removal of pollutants (sulfate)

& simultaneous charge functions

|

|

When using the battery for

a long time, accumulation of

sulfate causes battery lead

(Acid) to rust. This lowers

the efficiency of recharge as

well as battery Life.

Therefore, even rechargeable

batteries would not be recharged

as much as before. OPTIMORE

removes the sulfate within the

battery using high-frequency

pulse waves, which restores

the original battery capacity

and performance.

|

|

8.

Programmed to prevent future

sulfate rusting.

|

|

Sulfate is removed during

the OPTIMORE regeneration process.

It also prevents future accumulation

of sulfate on the lead, keeping

the restored state longer.

|

|

9.

Extends battery life by up to

twice as long.

|

|

Conventional charging methods

can not remove sulfate within

the battery. Therefore, expected

battery life is around 3 years.

However, with OPTIMORES¡®s

restoration capability, battery

life can be extended to more

than five to seven years.

|

|

10.

OPTIMORE equalizes the performance

all cells in the battery by

improving performance of the

inferior cells.

|

|

In case of battery with multiple

cells, the performance of an

inferior cell is severely lowered

with the lapse of time.

OPTIMORE

is able to identify these inferior

cells by an internal program,

and improves the performance

which equalizes the performance

of the battery as a whole.

|

|

11.

Can restore various types of

batteries (Pb, GEL, AGM types

and so on)

|

|

12.

Safety

|

|

- Keeps

temperature level low ; With

the optimal High-frequency Pulse,

prevents from the surge in temperature

occurred

by unnecessary conversion

of current to heat while regenerating

or charging.

- Minimize

the damage done to battery with

stable current and voltage supply

through Smart Control System

in MICOM.

- Prevents

build-up of sulfate from minimizing

damage to electrodes by optimized

high-frequency pulse.

- Minimize

evaporation of distilled water

by keeping low temperature level

during charging process.

-

Reduce the power consumption

by at least 70~90% compared

to conventional transformer

type regenerators.

|

| |

|

|

Why

should buy the OPTIMORE Battery

Regenerators?

|

|

¡Ü

Exclusive Advantages - All

New Innovation!

|

|

1.

Exclusive technology

|

|

- The most advanced and optimized

real high-frequency pulse regeneration

technology.

|

|

2.

Exclusive smart control system

and HF pulse charging curve

patterns in a high-grade

Micom.

|

|

3.

Exclusive regeneration software

algorithm

|

|

- Maximum restoration effect

and Minimal cell damage.

|

|

4.

Exclusive highest technology

basis advanced circuit system

design.

|

|

5.

Exclusive bubble figure

|

|

- The highest battery restoration

performance with micro bubble

desulfation process.

|

|

6.

Exclusive regeneration performance

|

|

- What could be better than

OPTIMORE? We are confident

that there¡¯s nothing better!

|

|

7.

Exclusive easy control and easy

user interface by push buttons set up

(EM-400E / 700M).

|

|

8.

Exclusive full automatic regeneration

process and fastest desulfation

& charge time.

(15 hours

including a full charge)

|

|

9.

Exclusive Graph output and printing

by USB connection with PC (Microscopic

analysis

of regeneration process).

|

|

10.

Exclusive elegant and modern

exterior housing design with

achromatic colors.

|

|

|

|

|

¡Ü

Special Advantages - All

New Innovation!

|

|

1.

Universal compatibility

|

|

-

All kinds of Lead-acid batteries

from 6V to 48V and 40Ah~400Ah.

(MD-400E / MD-700M)

-

All kinds of Lead-acid batteries

from 6V to 12V and 40Ah~300Ah.

(MD-200C / MD-300T)

|

|

2.

A full automatic operation by

very simple set up (The easiest

user interface).

|

|

3.

Excellent system durability

and stability

|

|

- Lowest defects by good

quality parts and stable system.

|

|

4.

Lowest power consumption. (e.g.

12V 100Ah = about 2 KW power

consumption totally)

|

|

- The highest battery restoration

performance with micro bubble

desulfation process.

|

|

5.

Adoption of various electrical

safety protection system.

|

|

6.

No battery explosion with the

advanced circuit system and

micro-bubble desulfation

process.

|

|

7.

Sustaining lower temperature

in the battery by automatic

output voltage & current

control.

|

|

8.

Satisfactory customer service

and quick after service.

|

|

9.

Portable light weights and easy

to carry.

|

|

10.

Using anywhere with AC220V single

phase or AC110V single phase.

(50~60 Hz)

|

|

|

|

¡Ü

We are proud that ModooTronix

Inc. in Korea is the most advanced

developer

and manufacturer for

the battery regeneration systems.

|

|

¡Ü

We have a full line up of battery

regenerators and dischargers

to make the

regeneration centers

in franchise.

|

|

|

|

|

Comparison

of Regenerator Old

Products(ZEUS)

and New

Products(OPTIMORE)

|

|

Description

|

Old

Product - ZEUS

(The

1st Generation Technology)

|

New

Product - OPTIMORE

(The

3rd Generation

Technology)

|

|

Model

No.

|

ZEUS

ZBR-A01 /

ZBR-A04

|

OPTIMORE MD-400E / MD-700M

|

|

System

|

SMPS

Type

|

SMPS

Type

|

|

Regeneration

Method

|

DC

with higher voltage

|

Optimized

High-Frequency Pulse

|

|

Strength

of Pulse

|

Intermittent

weak Pulse

|

Current

inclusive Pulse

|

|

Display

Monitor

|

3

inch Character LCD

|

75 x 25mm Character LCD

|

|

Initial

Setup Control

|

Button

Input Setup

|

Easy Button Input

Setup

|

|

Process

Type

|

Industrial

Micro Process (10bit

AD)

|

Industrial

Micro Process (10bit

AD)

|

|

Input

Power

|

AC

220V Single Phase

only

|

AC

200V ~ 250V Single

Phase

|

|

Allowed

battery Voltages

for

Identification

|

DC

12V Battery Only

|

No identification Mode with MD-400E / 700M

For Identification is by OPTIMORE EM-300T

(DC 6V~12V)

|

|

Battery

Voltages for

Regeneration/Charge

|

DC

12V ~ 48V

|

Adjustable

DC 6V ~ 48V

|

|

Battery

Capacity

|

Maximum

setting up to 300Ah

|

Maximum

setting up to 400Ah

|

|

Simultaneous

Regeneration/Charge

|

Up

to DC 48V

(DC

12V x 4 batteries & DC 2V x 24 batteries

in a serial connection)

|

Up

to DC 48V

(DC

12V x 4 batteries

& DC 2V x 24 batteries

in a serial connection)

|

|

Maximum

Output Current

|

Maximum

20A

(DC

6~36V : 20A, DC

48V : 15A)

|

Maximum

40A

(DC

6~48V : 40A)

|

|

Maximum

Power Cunsumption

|

800Watts

|

2.0KW

|

|

Discharge

Capacity

|

ZBR-A01

: Maximum

450W

|

MD-400E : without Discharger

MD-700M : with Discharger

|

|

Max.

Discharge Current

|

Maximum

30A (at 12V)

|

|

Operation

Mode

(Combined

functions)

|

ZBR-A01

: 4-in-1

1.

Identification Mode

(AUT)

2. Regeneration

Mode

3. Charge

Mode

4. Discharge

Mode

ZBR-A04

: 2-in-1

1.

Regeneration Mode

2.

Charge Mode

|

MD-400E

:

2-in-1

1.

Regeneration Mode

2.

Charge Mode

MD-700M

:

3-in-1

1.

Regeneration Mode

2.

Charge Mode

3. Discharge Mode (10kW)

|

|

Bubble

figure

in Electrolyte

when Regeneration

|

Air-bubble

figure

|

Micro-bubble figure

(World Exclusive Feature)

|

|

Net

Weight

|

Approx.

8Kg / 5Kg

|

MD-400E : Approx. 17Kg

MD-700M : Approx. 70Kg

|

|

Usage

|

All

kinds of lead-acid

battery of

DC

6V ~ DC 48V

|

All

kinds of lead-acid

battery of

DC

6V ~ DC 48V

|

|

Merits

|

1.

Easy Operation

2.

Portable type, Convenient

to carry

3.

Minimized Power

Consumption

|

1.

Included all upgraded

functions of ZBR-A04

2. Convenient

setup by push buttons

3. Elegant

exterior design

with achromatic

colors

4. Variable

regeneration methods

by Power supply Mode

5.

Highest technology

basis advanced circuit

system design

6.

Lowest defects by

good quality parts

and stable system

7.

Reducing regeneration

time against others

8.

Optimized high-frequency

pulse desulfation

9. No explosion

with fine-bubble

desulfation process

|

|

Demerits

|

1.

It must improve

all system as the

first-generation.

2. Need

to reinforce its

Durability

3.

Analog Interface

System and Display

4. Old exterior

design and low-priced

system

|

N/A

|

|

Product

Image

|

|

|

|

|

|

|

|

|

|

|

|

|

|